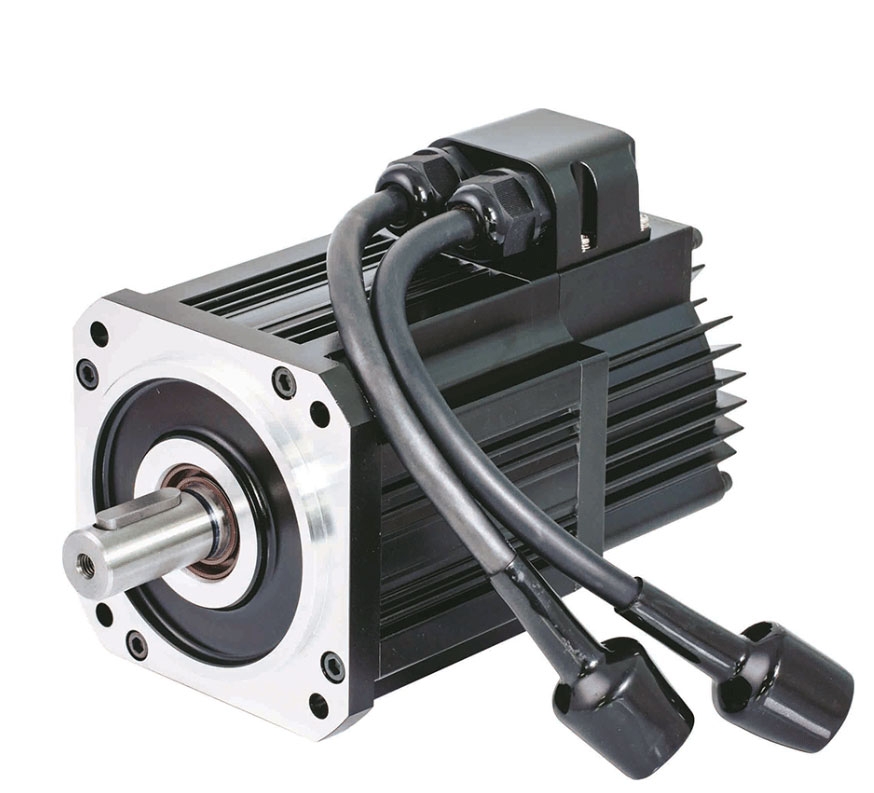

Servo Motor Wiring Harness Processing

Types of Connectors That Can Be Processed

Power Connectors

- Used to supply the electrical power required for servo motor operation.

- Common specifications: highvoltage or lowvoltage connectors.

- Compatible with heatresistant or highflexibility cables.

Brake Connectors

- Used to control the braking function of the servo motor.

- Special wearresistant materials are available, ideal for dynamic braking needs.

Encoder Connectors

- Responsible for data transmission, detecting the motor's rotational position and speed.

- Options include highprecision signal cables and antiinterference materials.

Available Cable Options

- HighFlex Cables: Suitable for highfrequency bending scenarios, such as robotic arms or mobile equipment.

- HeatResistant Cables: Designed for hightemperature environments, such as near industrial ovens.

- Shielded Cables: Effectively prevent electromagnetic interference, ensuring signal stability.

- OilResistant and WearResistant Cables: Ideal for industrial environments with oil stains or abrasion.

Processing Services and Customization Options

- Connector Types: Support for both standard and customized specifications.

- Cable Length: Tailored to actual requirements.

- Overall Protection: Comprehensive protective sleeves are available to extend service life.

Waterproof Servo Motor Connector Wiring Harness Processing

We also offer waterproof connector processing services for servo motor wiring harnesses, utilizing highgrade waterproof connectors (IP65, IP67, IP68). These connectors feature sealed structures to ensure excellent waterproof performance.

Key Features of Waterproof Harnesses

- HeatResistant Cables: Suitable for hightemperature industrial environments.

- HighFlex Harnesses: Ideal for mobile equipment or applications requiring frequent bending.

- OilResistant and WearResistant Harnesses: Designed for harsh industrial automation environments.

Customization Services

- Various connector types: circular, rectangular, multipin, etc.

- Support for different cable lengths and specifications.

- Additional protection, such as outer protective sleeves or shielding layers, for special environments.

Encoder Wiring Harness

The encoder wiring harness is an electrical connection solution specifically designed for encoder devices. It ensures precise data transmission and reliable power connectivity. With a streamlined structure and highquality connectors and cables, it meets the highprecision requirements of industrial automation, machinery, and motion control applications.

Key Features

- HighPrecision Connectivity: Ensures accurate signal transmission from the encoder, enhancing system stability.

- Multiple Connector Options: Supports Dsub, M12 circular connectors, and more to suit different encoder models.

- Durable Cables: Made with ULcertified highflexibility cables that withstand repeated bending for extended service life.

- Electromagnetic Interference Protection: Shielded design minimizes external signal interference.

- Customizable: Tailored cable lengths, termination methods, and connector models to meet various application needs.

Applications

- Industrial Automation Equipment: Enhances encoder reliability in robotic arms, conveyor belts, and automated production lines.

- Motion Control Systems: Used in CNC machines, servo motors, robots, and other devices requiring precise positioning.

- Machinery: Supports applications that require speed and position detection, such as printing machines and packaging equipment.

For inquiries or quotes, please provide the specific servo motor model, wiring specifications, and application requirements. We will recommend the optimal solution for your needs!