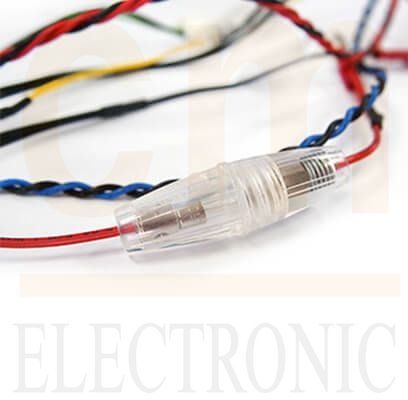

Fuse Holder Wire Harness

What is Fuse Holder Wire Harness?

Fuse holder wire harnesses are critical components in electrical systems, providing essential circuit protection while enabling convenient installation and maintenance. These assemblies combine protective housings for fuses with pre-assembled wiring, creating an integrated solution for various applications.

Applications of Industrial Fuse Holder Wire Harness

Automotive Industry

In the automotive sector, fuse holder wire harnesses serve multiple critical functions:

- Protection of essential vehicle electrical systems including lighting, entertainment, and climate control

- Battery circuit protection and power distribution management

- Integration with vehicle diagnostic systems

- Support for aftermarket electrical accessories

Industrial Equipment

Industrial applications require robust and reliable protection:

- Manufacturing equipment circuit protection

- Power distribution panels in factories

- Control system protection in automated machinery

- Heavy equipment electrical system protection

Consumer Electronics

In consumer and commercial electronics:

- Power supply protection in high-end audio equipment

- Circuit protection in professional broadcasting equipment

- Safety systems in commercial appliances

- Backup power system protection

Technical Specifications

Electrical Specifications

Key electrical parameters include:

- Voltage Ratings:

- Low voltage: 32V DC for automotive applications

- Medium voltage: 250V AC for commercial applications

- High voltage: Up to 600V for industrial applications

- Current Ratings:

- Standard range: 0.5A to 30A

- Heavy-duty options: Up to 100A for specialized applications

- Ultra-low current options: Down to 0.1A for sensitive electronics

- Circuit Protection:

- Fast-blow options for sensitive equipment

- Slow-blow designs for motors and high-inrush current applications

- Resetable variants for specific applications

Environmental Specifications

Environmental durability features:

- Temperature Range:

- Operating: -40°C to +105°C

- Storage: -55°C to +125°C

- High-temperature variants available for specific applications

- Protection Ratings:

- IP65 for dust-tight and water jet protection

- IP67 for temporary immersion protection

- IP68 for continuous submersion in specified conditions

- Vibration Resistance:

- 10-500Hz frequency range

- Up to 10G acceleration

- Meets automotive and industrial standards

Physical Specifications

Design and construction features:

- Housing Materials:

- High-grade thermoplastics for standard applications

- Glass-filled nylon for enhanced durability

- High-temperature polymers for extreme conditions

- Terminal Types:

- Quick-connect tabs (0.250", 0.187")

- Screw terminals for secure connections

- Solder terminals for permanent installation

- Ring terminals for high-current applications

- Wire Specifications:

- Standard: 18-12 AWG

- Heavy duty: Up to 4 AWG

- High-temperature rated insulation options

Why Chan Ming Fuse Holder Wire Harness?

Safety Features

Critical safety elements include:

- Touch-safe design preventing accidental contact with live parts

- Positive fuse retention mechanisms

- Clear fuse state indication

- Polarized connections to prevent incorrect installation

- Overcurrent and short-circuit protection

Installation Features

Features facilitating easy installation:

- Mounting Options:

- Panel mount designs

- Surface mount configurations

- DIN rail mounting capabilities

- Custom mounting solutions

- Wire Management:

- Integrated strain relief

- Wire routing guides

- Protective sleeving options

- Cable tie anchor points

Maintenance Features

Design elements supporting maintenance:

- Tool-free fuse access in many designs

- Clear fuse rating markings

- Easy-to-use test points

- Modular construction for component replacement

Industry Standards and Compliance

Fuse holder wire harnesses must meet various standards:

- Automotive: SAE, ISO, and USCAR specifications

- Industrial: UL, CSA, and IEC certifications

- Environmental: RoHS and REACH compliance

- Safety: Various regional safety standards and regulations

Selection Considerations

Key factors in choosing appropriate fuse holder wire harnesses:

- Circuit requirements (voltage, current, interrupting rating)

- Environmental conditions (temperature, moisture, vibration)

- Space constraints and mounting requirements

- Maintenance accessibility needs

- Cost considerations for the application

Future Trends

Emerging developments in the industry:

- Integration of smart monitoring capabilities

- Enhanced environmental protection features

- Development of higher temperature materials

- Integration with vehicle network systems

- Advanced diagnostic capabilities